‘Bidirectional Fabrication’ combines two previously separate design practices – digital 3D modelling and physical shaping by hand – and makes them both part of the same process. This overcomes the problem that designers are tied into digital modelling tools allowing them to truly get hands on to create novel products and to allow the design process to stay in the physical world.

Providing a flexible design process that allows objects to evolve through computer aided design and physical modifications, bidirectional fabrication enables hands to do the jobs they are good at, such as shaping and detailing, and the computer can do actions it is best at, such as drilling precise holes and making perfectly flat surfaces.

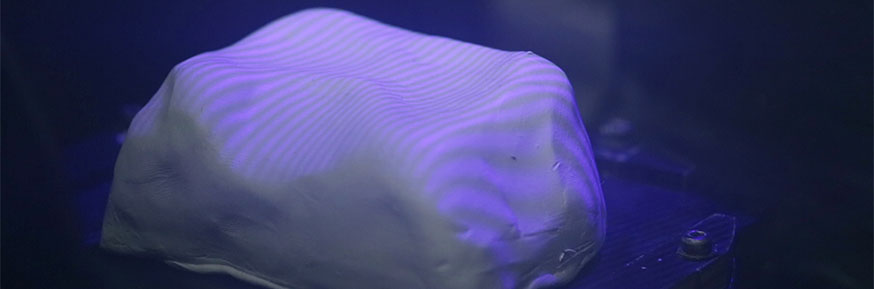

Researchers at Lancaster University’s School of Computing and Communications have created ReForm, a machine that enables bidirectional fabrication through the use of polymer clay. ReForm incorporates a scanner to scan physical objects including existing objects or the clay model, a custom-built 3D printer for adding clay, a milling tool for removing clay and a projected augmented reality display to overlay information such as colours and textures.

It enables the design process to be continuous and evolutionary. Refinements to a clay product model can be made by hand and then scanned to create a digital version, which can then be modified using software. These changes can then be made by ReForm to the clay model. Further changes can then be made by hand and so on, so the process runs in a closed loop with the user and machine taking turns, enabling rapid adjustments to be made

Dr Jason Alexander, a lecturer in Human-Computer Interaction and project lead, said: “Before you had to be an expert in computer aided design. ReForm means you no longer have to be a technical expert to design objects for 3D printing. People can get hands-on and iteratively and inexpensively design objects in a much more efficient way.

“We will find that people will be able to create artefacts for 3D printing that are a lot more creative and fit for purpose.”

If a mistake is made, or the model accidentally dropped, ReForm is able to return the physical model to a previously saved version by using its tools to add or remove clay where necessary.

Users can also use a pen to draw commands onto the surface of the model, such as a cross or a circle. ReForm will then drill holes, 3D print clay or create a pattern where the marks were drawn, making it very simple for users.

The ReForm process eliminates restrictions such as virtual digital designs needing to be completed before a model can be fabricated. It also helps to save materials as the clay used can be recycled.

Christian Weichel, now at Bosch, said: “ReForm blurs the lines between the physical and digital worlds allowing users to design objects in the most suitable environment."

The technology, which is described in the paper ‘ReForm: Integrating Physical and Digital Design through Bidirectional Fabrication’ and will be presented at UIST, in North Carolina on November 9, is demonstrated in a video here: https://youtu.be/_LUju_068n0

The researchers have so far been able to use ReForm to create prototypes of products such as a smartwatch strap, a console game controller, a key hook and a smart phone docking station.

The project, which involved researchers Christian Weichel, John Hardy, Jason Alexander, and Hans Gellersen, was funded by the European Commission through the FET-open programme via the GHOST project: www.ghost-fet.com

More information about Lancaster University’s School of Computing and Communications can be found by visiting http://www.lancaster.ac.uk/scc/