Carbon dioxide utilisation

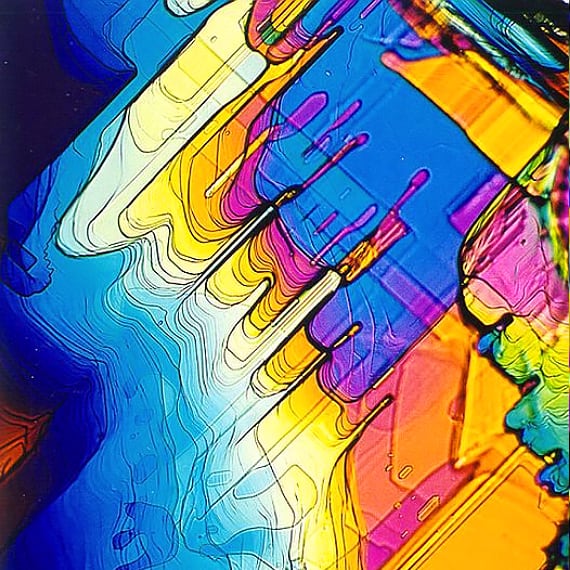

Reactions between CO2 and epoxides are one of the most promising applications for chemical utilization of CO2 as a renewable carbon source in the production of carbonates. The research led by Dr Vesna Najdanovic aims to enhance yields and selectivity of organic carbonates production by phase equilibrium-controlled kinetics.

Organic carbonates are valuable synthetic products, with diverse applications such as polar aprotic solvents, electrolytes for lithium batteries, fuel additives and intermediates in the manufacture of chemicals. In this work, the production of various organic carbonates from corresponding epoxide and carbon dioxide under high-pressure is studied. Reactions in high-pressure dense CO2 are versatile - they can be carried out either in a single phase or in a biphasic system simply by adjusting pressure and temperature. There are numerous examples in the literature where a homogeneous single-phase offers more favourable conditions for fast reaction rates and chemo-selectivity.

In other circumstances, it is a heterogeneous system that can dramatically increase reaction rate or influence the outcome of a reaction due to the ability of CO2 to bring the gaseous reactants into the liquid medium, facilitating mass transfer. These effects of CO2 pressure and temperature on the organic carbonate formation are investigated in this project.

This integrated approach to study reaction kinetics and phase equilibria is a useful tool to determine the conditions of pressure and temperature under which the maximal concentration of the reactants in the vicinity of the catalyst is achieved, substantially improving attainable yields over the current state-of-the-art.

Waste as resource: extraction of valuable substances

One of the challenges facing food and agriculture industry is how to process waste materials to create valuable products. The research led by Dr Vesna Najdanovic aims to develop new and innovative ways to convert waste into useful products by creating a resource from the residual materials, including fermentation broth, agricultural and food industry wastes.

New technologies such as pollution controls and combustion engineering have advanced to the point that emissions from burning biomass in industrial facilities are generally lower than emissions produced when using fossil fuels. The volume of biomass available to be burned is increasing, and therefore it is possible to extract a significant amount of valuable chemicals in relatively large volume, given the volumes of available biomass. Many of these chemicals (antioxidants, nucleotides, oils etc.) have a high value on the market. The aim of this project is to characterise and recover various useful chemicals from residual biomass including fermentation broth, olive stones, nettles and so forth.

Clean energy utilisation from biogas and biomass gasification

This project aims to develop realistic and predictive physicochemical models for biogas and bio-syngas combustion and mappings between the combustion and emission characteristics and the fuel compositions for clean energy utilisation from renewable gaseous fuels.

The project will provide a better understanding of the complex physicochemical processes of bioenergy utilisation, which can advance bioenergy technology towards deployment. Based on rigorous modelling and experimentation, the project will deliver a thorough understanding of the utilisation of biogas and bio-syngas, highlighting the effects of variable composition.

Biodiesel production from waste biomass

Food-based feedstock for biodiesel production is limited by competition with land used for food production, which makes sustainability a critical issue. Therefore, in the last decade, an effort was made in developing the use of agricultural waste as alternative raw materials for biodiesel production. This project led investigates in-situ transesterification of spent coffee grounds, coupling extraction and conversion in one pot operation.

Europe produces large amounts of spent coffee grounds (SCGs) which is a vast resource of lipids and lignocellulosic material. SCGs contain on average up to 20 % of lipids (87–93% of which are triglycerides) that can be converted to biodiesel and lignocellulosic material which can be an energy source in the form of fuel pellets. The cost of raw materials, mainly oil and methanol, accounts for 75–90% of the total cost of biodiesel, and thus, the use of low-cost oil-rich residues, such as SCG, can have a significant effect on the economy and the environmental impact of biodiesel production.

.jpg)